Author: Jamie Hunt

Stainless Steel is an Iron alloy which contains a minimum of 10.5% Chromium. The Chromium reacts with Oxygen when present on its surface to form a passive Chromium Oxide film. This prevents the Iron in the stainless from oxidizing and rusting. See how stainless steel works here.

Different grades of stainless steel and which grade to use for an application will largely come down to:

Here is a guide on stainless steel use and selection.

316 grade stainless has the element of Molybdenum added (only 2%). This adds a significant improvement to its ability to withstand corrosion over 304 and avoid rusting and mild rust stains often called ‘tea-staining’.

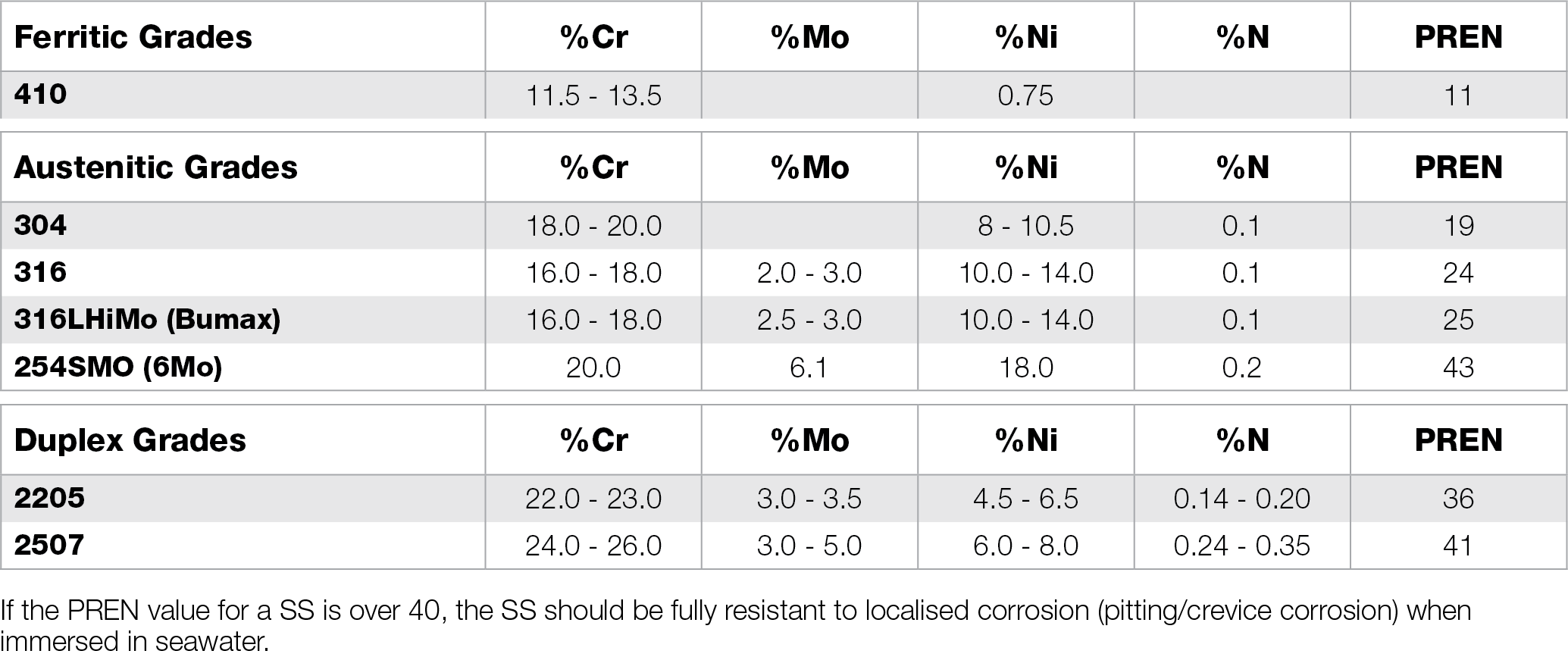

For internal use and environments with a low degree of corrosivity, then 304 grade might be fine. However for external and coastal applications 316 grade might be best. For salt water applications Duplex 2205 grade is suitable if tidal, but Super Duplex 2507 would be required if submerged.

Pitting Corrosion resistance can be estimated and calculated by a PRE value or PREN (Pitting Resistance Equivalent Number), which is an approximate guide for the corrosion resistance of each grade of stainless steel.

What is marine grade stainless? For salt water applications such as being submerged or as keel bolts then Super Duplex 2507 would be more suitable to eliminate the risk of unwanted corrosion. With the increased levels of Chromium and Molybdenum, Super Duplex 2507 is far more immune to pitting corrosion from Chloride attack.

Super Duplex has a PREN value of 40, making it a ‘Super’ grade and ideal for submerged salt-water applications.

For more information or technical advice please contact the Nickel Institute or the Australian Stainless Steel Development Association (ASSDA).

Jamie Hunt is the CEO of Anzor Fasteners LLP, with 23 years of procurement and supply of Stainless Steel Fasteners and Hardware under his belt. He also has Olympic yachting experience and is a Certified ISSF Stainless Specialist.

Jamie is a member of the Australian Stainless Steel Development Association and has written many articles including "The Stainless Steel Guide", "Can you paint stainless steel?" and "Are stainless fasteners OK with treated timber?". Check out Jamie on his LinkedIn profile for more information.

Build Your Deck Faster With Our Decking Screw Calculator

Super Duplex 2507 Stainless Steel for Engineering & Manufacturing

To receive useful info and product updates add your details below